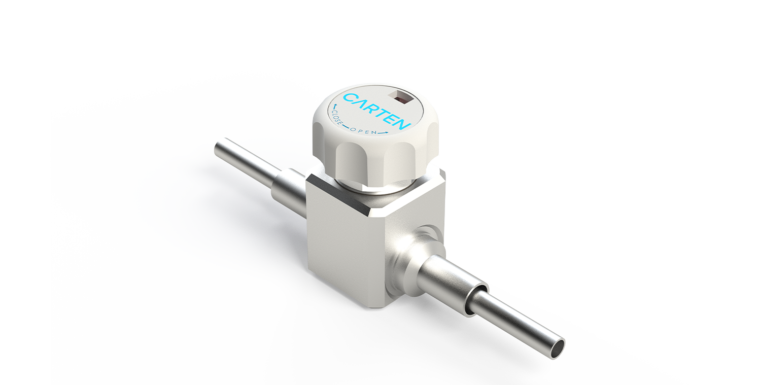

DCS Series

Ultra-High Purity Dual Containment Diaphragm Valves

The DCS series provide the safety of a complete secondary containment flow path, that remains open regardless of the primary passage being opened / closed, creating a sealed secondary barrier against the most toxic, corrosive, and dangerous gases.

Key Features

Available in line sizes up to ¾” (primary) / 1” (secondary)

Metal-to-metal external seals for both flow paths

Pneumatic or manual interchangeability

Fully metal-sealed secondary containment layer

Typical Applications

Lateral points-of-connection (POC), tool hook-up shut-off, ultra-high-purity gas control for point-of-use service, valve manifold boxes (VMB), gas distribution panels, gas sticks, and critical application containment functionality.

Key Specifications

| Materials of Construction | Cleanliness | Specifications | Options |

|---|---|---|---|

| 316L stainless body |

Manufactured in Class 10 Cleanroom |

Leak tested using Mass spectrometer <1x10(-9) mbar.l/s |

Manual or pneumatic |

| Stainless 316L Diaphragm (both flow paths) |

Zero particles @0.1µm |

<10Ra micro-inch surface roughness |

PFA / PI seat high temperature (up to 150C) |

| Barstock-only source |

<10ppb O2/H20 outgassing |

Vacuum and pressure tested 100% production control |

4/20mA switching / signalling automation |

| PCTFE standard seat (minimal volume) |

Cleaned using 18.2MΩ·cm DI water |

250p.s.i. operating pressure |

0.41 – 1.2 Cv (flow coefficient) |